10 Key Data Cable Cost Factors to Optimize Customized Production.

Introduction to data cable cost. Understanding the importance of factors that affect mobile cable cost is essential for consumers looking to make informed purchasing decisions. In this blog, we will discuss the key factors that influence the charging cable cost.

Quality of materials used:

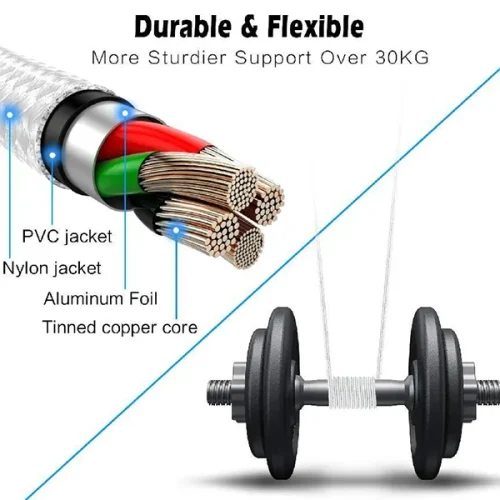

The quality of materials used in data cables has a significant impact on their performance and durability. The materials that can directly affect the cost and quality of USB mobile data line are mainly as follows:

- Core Materials: Different core materials are used in data cable manufacturing such as iron core, galvanized iron core, copper plated iron core, copper, aluminum and optical fiber. The choice of material affects the cable’s ability to effectively transmit data and withstand wear and tear, with the best performing ones being pure copper cores. Higher quality materials often result in higher costs due to their superior performance and longevity.

- Jacket material: Jacket material refers to the protective layer of the data cable. It plays an important role in determining the overall cost. Different sheathing materials have different costs and properties. For example, PVC sheathing is cost-effective but may not provide the same level of durability as materials like TPE and braid. Click to read detailed jacket material knowledge.

- Port Shell: The shell material refers to the outermost layer of a data cable connector port that protects the internal components. It affects the overall cost of the cable. Different housing materials have different costs and characteristics. For example, aluminum housings are lightweight and cost-effective, while stainless steel housings are more durable but more expensive.

Function:

PD (Power Delivery), QC (Quick Charging) and OTG (Mobile) support are basic features required when evaluating data cable costs. These features allow for faster charging, data transfer, and connectivity options. The inclusion of these features can impact the cost of data cables. Cables with PD, QC, and OTG support generally have higher prices due to the added functionality.

Data transmission capabilities is a significant data line cost factor. Higher data transfer speeds and compatibility with advanced technologies like USB 3.1 or Thunderbolt can increase the cost of data cables. Cables with superior data transmission capabilities are often priced higher due to the advanced technology involved.

Exploring the Concept of One Drag Two/Three and its Effect on Data Cable Cost One Drag Two/Three refers to the ability of a data cable to simultaneously charge multiple devices or transfer data to multiple devices. This feature can impact the cost of the cable. Cables with One Drag Two/Three capabilities tend to be more expensive than those without this feature due to the additional functionality provided.

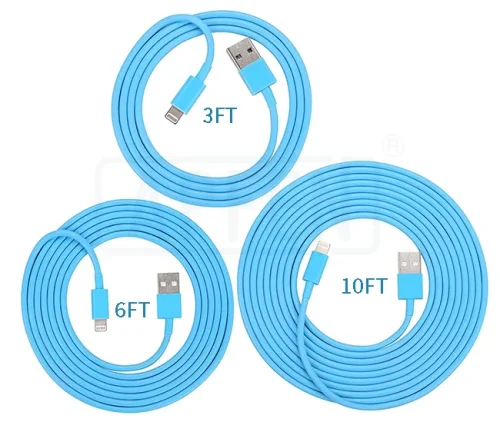

Cable length and thickness:

The length of a data cable is directly related to its cost. Longer cables require more materials and manufacturing processes, resulting in higher prices. When choosing the appropriate cable length, factors such as the distance between devices and the intended use should be considered. Additionally, cable thickness plays a crucial role in data transmission and charging speed. Thicker cables generally have better conductivity and can handle higher currents, but they may also be more expensive due to the increased material required. For example, the diameter and quantity of copper wire used in data cables can influence the cost. Thicker copper wires are generally more expensive due to the increased material costs. Similarly, cables with a higher quantity of copper wire may have a higher price tag due to the additional materials required.

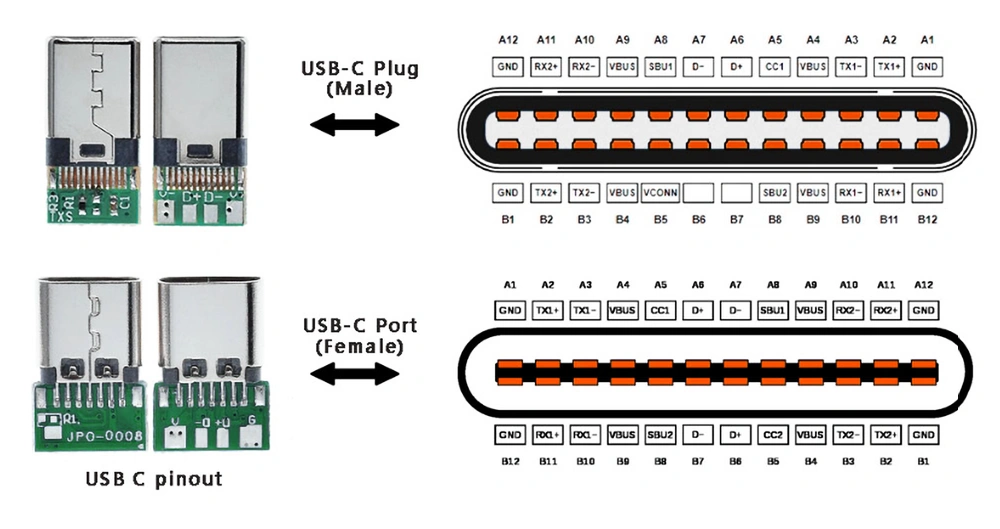

Type of connector:

Data cables come with different types of connectors, such as USB-A, USB-C, Lightning, and HDMI. The compatibility between connectors and devices is essential for seamless data transfer and charging. The choice of connector materials, such as gold-plated or nickel-plated connectors, can also impact the cost. Connectors with higher-quality materials may be pricier, but they often offer better durability and reliability. Click here to learn more about the different USB connector types.

Brand reputation:

Brand reputation plays a significant role in data cable manufacturing. Established brands known for producing high-quality cables often have higher prices due to their reputation for reliability and performance. These brands invest in research and development, ensuring that their products meet industry standards and consumer expectations. While opting for reputable brands may result in a higher cost, it can provide peace of mind and a longer lifespan for the data cable.

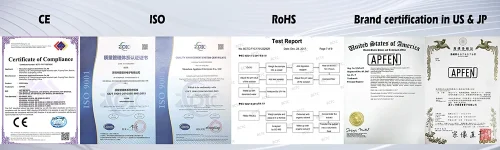

Certification and compliance:

Certifications and compliance standards are vital for data cables. These certifications ensure that the cables meet specific quality and safety requirements. Choosing certified and compliant cables guarantees that they have undergone rigorous testing and adhere to industry standards. However, the cost of obtaining certifications and compliance can impact the overall price of data cables. But at APPHONE, we have obtained comprehensive certification systems such as MFI, USB, RoHS, CE, FCC, reach, UL, ISO, etc. We still will not count these costs on customer orders, because we feel that this is what we should do to gain the trust of customers. Only by being sincere and reciprocating can we have long-term cooperation.

Customized Packaging:

Customized packaging is one factor that significantly affects the cost of data cables. Customized packaging provides an opportunity for companies to effectively market their brand and create a lasting impression on customers. By incorporating their logo, colors, and unique design elements on the packaging, companies can enhance brand recognition and differentiate themselves from competitors. However, such branding efforts often entail additional expenses, which ultimately contribute to the overall cost of data cables. The choice of packaging material is another crucial factor affecting the cost of data cables. While standard packaging materials like cardboard boxes are relatively affordable, opting for premium materials such as eco-friendly or high-quality materials can significantly increase the production costs. Companies must carefully assess the desired level of packaging aesthetics, durability, and sustainability, as these factors directly impact the final cost of the data cables.

Order quantity:

The order quantity refers to the number of cables that a buyer intends to purchase in a single order. This factor plays a crucial role in determining the overall cost of data cables for several reasons.

Firstly, economies of scale come into play when it comes to order quantity. Data cable manufacturers often offer discounts for bulk orders. The larger the order quantity, the higher the chances of negotiating a lower price per unit. This is because manufacturers can take advantage of producing data cables in large quantities, reducing their production costs and passing on the savings to the buyer. Therefore, a larger order quantity can result in significant cost savings for the buyer.

Secondly, the order quantity affects shipping and handling costs. When data cables are ordered in smaller quantities, the cost of packaging, transportation, and handling per unit becomes relatively higher. This is because the fixed costs associated with shipping and handling are divided among a smaller number of cables, resulting in a higher cost per unit. However, when larger quantities are ordered, the fixed costs are spread over a higher number of cables, resulting in lower shipping and handling costs per unit.

Furthermore, the order quantity affects inventory management costs. For buyers who regularly require data cables, ordering in larger quantities can help reduce the need for frequent orders and restocking. By ordering in bulk, buyers can take advantage of economies of scale and reduce the administrative costs associated with placing orders and managing inventory. This can lead to cost savings in terms of time, labor, and paperwork.

Online vs offline purchasing options:

The availability of online and offline purchasing options has implications for data cable costs. Purchasing data cables online offers benefits such as convenience, a wide selection of options, and the ability to compare prices easily. Online retailers may also offer discounts and promotions, resulting in lower overall costs. Offline purchases, on the other hand, allow customers to physically examine the cables before buying, but they may be subject to higher prices due to overhead costs associated with brick-and-mortar stores.

Market demand and competition:

Market demand and competition among manufacturers influence data cable pricing. Higher demand for specific cables can drive up prices, especially if supply is limited. On the other hand, intense competition can lead to price reductions as manufacturers strive to attract customers. Considering market demand and evaluating the competitive landscape can help consumers understand the pricing dynamics of data cables.

In our blog, we take a closer look at the top ten key factors that influence data cable costs. From material selection to production process, every detail has a significant impact on final electronics cable costs. Understanding these factors is crucial for consumers looking to make informed purchase decisions. The quality of materials used, cable length and thickness, type of connector, brand reputation, certification and compliance, customized packaging, market demand and competition, order quantity, and purchasing channels all play a role in determining the cost of data cables. As we understand that the quality and performance of customized USB cables is critical to our customers, we must control costs while ensuring quality. Make an informed decision and enjoy seamless data transmission and charging with the right data cable.

For your next USB cable project, we encourage you to take a deep dive into these factors and work with a professional manufacturer to ensure you get the highest quality product while minimizing cost. Through sound material selection, innovative design, and efficient production processes, you can provide your customers with outstanding products while achieving higher profits. If you have a need for large quantities of USB cables, please feel free to contact us. We will use our years of professional production experience to provide you with high-quality customized cable solutions with cost advantage.

Fast delivery

Fastest delivery within 22 days

Quick proofing

Fastest 3-day proofing cycle

After-sale protection

24-month long warranty

1V1Customer Service

Professional customer service follow-up