USB C Positive and Negative Wires Comprehensive Guide

USB-C is everywhere these days, charging your phone, connecting your laptop, even powering your camera. With its compact design and reversible connector, USB-C offers significant advantages over its predecessors. It includes faster data transfer rates, higher power delivery capabilities, and enhanced versatility. It’s super convenient, but have you ever wondered what’s going on inside those tiny connectors?

In this article we will look into the wiring of USB-C cables. We will mainly focus on the positive and negative wires. And will try to understand the role and designation of these wires, so you can ensure safe and efficient use of USB-C technology in your devices and projects. This information will be of great use when working with USB-C wiring. Keep reading…

What is USB C Positive and Negative Wires?

USB-C positive and negative wires are essential components in USB-C cables, playing a crucial role in both power and data transmission. In this part of our article, we will know what these positives and negative wires are and how they contribute to the functionality of USB-C cables.

- USB-C Positive Wire

The positive wire in a USB-C cable is responsible for carrying the power or voltage needed to charge devices or power peripheral devices. This wire is typically represented by the color red in USB-C cable color coding. It connects to the VBUS (Voltage Bus) pin in the USB-C connector, which supplies power to the connected device. In addition to carrying the power or voltage required to charge a device or power peripherals, it is instrumental in facilitating data transmission. However, it’s important to clarify that the data transmission doesn’t occur directly through the negative line. Instead, there are independent data transmission line groups: TX1+/D1+/RX2+ for the positive data transmission channel, which works in conjunction with the corresponding TX1-/D1-/RX2- negative data channel to ensure efficient and seamless data transmission between devices. - USB-C Negative Wire

The negative wire in a USB-C cable performs a vital role in completing the electrical circuit, serving as the return path for the current flowing through the positive wire. Beyond its primary function in electrical flow, this wire also contributes to maintaining stable data transmission. Typically identified by the color black in USB-C cable color coding, it connects to the Ground (GND) pins within the USB-C connector. This connection ensures proper grounding, which not only improves electrical stability but also helps stabilize data transmission. By effectively grounding the system, the negative wire ensures that data signals are reliably transmitted between connected devices, enhancing overall performance and reliability.

How Positive and Negative Wires Facilitate Power Transmission?

Any type of USB cable needs to have a complete positive and negative line working together to achieve efficient power transmission. The positive wire carries the power supply from the power source to the device that needs charging or powering. The negative wire provides the return path for the current, allowing the electrical circuit to be completed. This ensures that power flows smoothly and efficiently from the power source to the device. This collaboration between the positive and negative wires ensures that your devices receive the necessary power safely and reliably.

How Positive and Negative Wires Facilitate Data Transmission?

In addition to power transmission, USB-C cables are used for data transfer between devices. Here’s how the positive and negative poles in USB contribute to this process:

- Power for Data Transmission: While the positive and negative wires primarily handle power transmission, they also play a role in powering the electronics within the cable that manage data transfer.

- Signal Integrity:These wires help maintain the integrity of the data signals during transmission, ensuring that electronic information is transferred reliably and accurately between devices like computers, smartphones, printers, and monitors.

- Supporting Data Lines:USB-C cables contain additional wires dedicated to data transmission, supporting higher USB versions. These data lines, such as USB 3.0 Data+ (D+) and USB 3.0 Data- (D-), provide faster data transfer speeds compared to the earlier USB 2.0 standard. The positive and negative wires in the USB-C cable support these high-speed data lines by providing the necessary power and grounding, which helps mitigate electrical noise and interference, ensuring reliable data transmission. Click here to view more detailed knowledge of USB data transmission standards.

We can say that the positive and negative wires in USB-C cables are essential for both power delivery and data transmission. The positive wire carries the power needed by devices, while the negative wire completes the circuit, ensuring stable power flow. Together, they also support the data transmission process by maintaining signal integrity and providing the necessary electrical environment for reliable data exchange.

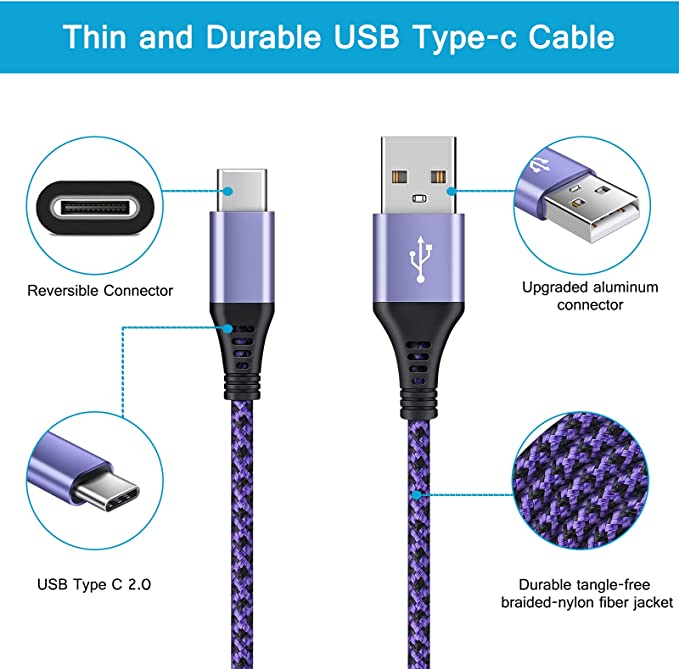

Understanding USB C Cable Construction

USB-C cables are designed to support high-speed data transfer, power delivery, and video output, all within a compact and reversible connector. To understand how USB-C cables achieve this, let’s know more about their structure, materials. Also, how the positive and negative wires are integrated into the overall cable construction.

USB-C Cable Structure

A typical USB-C cable consists of multiple layers and components, each serving a specific purpose to ensure efficient and reliable performance. For instance, the outermost layer of the cable, usually made of a durable and flexible material like PVC (Polyvinyl Chloride) or TPE (Thermoplastic Elastomer). This jacket protects the internal components from physical damage and environmental factors.

Beneath the outer jacket, there are layers of shielding. Shielding can include:

Braided Shield: A mesh of conductive material (often copper or aluminum) that protects against electromagnetic interference (EMI) and radio frequency interference (RFI).

Foil Shield: A layer of aluminum foil that provides additional protection against interference.

For more detailed USB cable structure, please visit the corresponding blog.

APPHONE understands that ordering custom USB cables in bulk is a major move related to business development. Therefore, we have partnered with Amazon Retail to create a trial event where you can use the discount code (7L9LY3LV) to order a small number of USB A to lightning right-angle cables at a super low price to disassemble and analyze their internal structure.

*This discount is an exclusive discount for bulk customers to obtain samples, helping B-end customers reduce upfront costs and shipping time. Please do not spread it around.

I hope this event will allow you to personally disassemble our nylon braided right-angle USB A cable at a very low price. Evaluate our rigor of USB cable structure manufacturing from internal materials, positive and negative wire quality, shielding protection and electrical performance. If you have specific transmission requirements for USB cable data positive and negative wires or power positive and negative wires, you can contact us at any time, and our experienced team of engineers will meet your needs according to the configuration of the positive and negative wire gauges and wiring methods.

Moving on, individual wires within the cable are insulated with a plastic material to prevent short circuits and cross-talk between wires. Common insulation materials include polyethylene (PE) and polypropylene (PP). Data wires are often arranged in twisted pairs to reduce electromagnetic interference and maintain signal integrity. Twisting the wires helps cancel out noise and interference from external sources.

The core of the cable consists of multiple conductors. These conductors are typically made of copper for its excellent conductivity. Each conductor is responsible for carrying specific signals, such as power, data, or video. The positive and negative wires are critical components within the USB-C cable, responsible for delivering power and data transmission respectively. Here’s how they are integrated into the cable structure:

The positive wire carries the electrical power from the power source to the connected device. It is usually made of a high-conductivity material like copper and is insulated with a durable plastic to prevent electrical shorts. The positive wire connects to the VBUS pin in the USB-C connector, which is responsible for supplying power to the device.

The positive and negative wires in a USB-C cable are responsible for both power delivery and data communication. The negative wire provides the return path for the electrical current, completing the power circuit. However, it’s essential to note that power and data transmission are not on the same line; each has an independent line group. The positive wire, responsible for power delivery, typically connects to the VBUS pin in the USB-C connector, while the negative wire, besides completing the power circuit, also connects to the Ground (GND) pins, ensuring proper grounding and electrical stability for the data signals.

Which Wires Are Positive And Negative In Usb C?

In USB-C cables, the positive and negative wires are essential for carrying power and completing the electrical circuit. Identifying these wires can sometimes be done through color coding, although this can vary between manufacturers. Below, we will discuss the common standards and how to identify these wires.

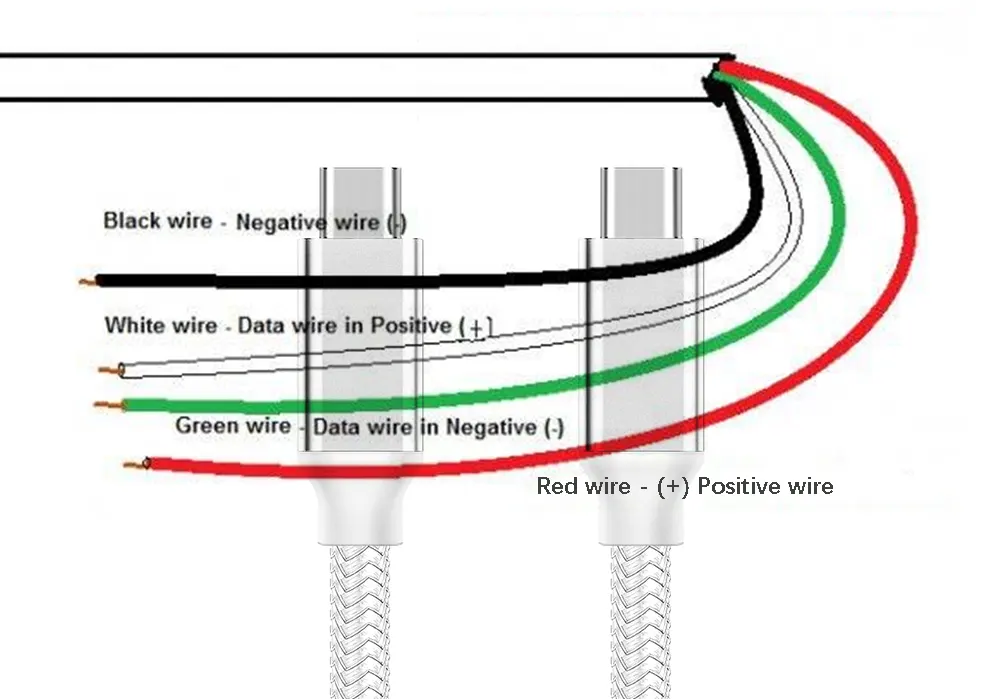

USB Wire Color Coding:

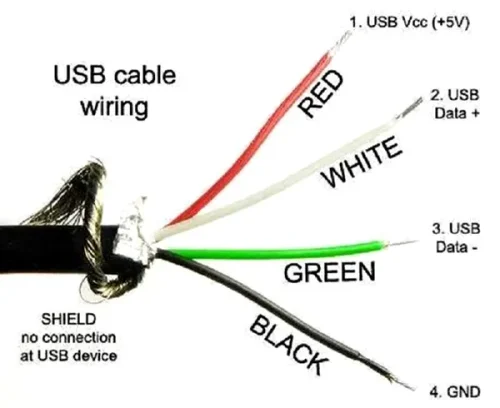

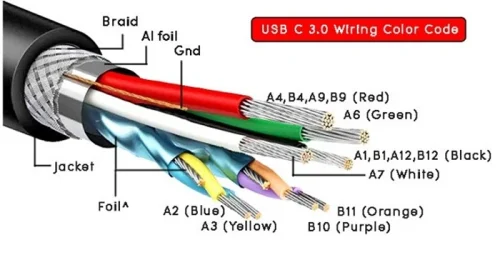

Commonly, a USB cable contains four wires inside. Two of these wires are used for power delivery, while the other two are responsible for differential serial data signals, enabling data transfer. However, with the introduction of USB 3.0, the cable design has become more complex.

USB 3.0 utilizes a total of ten wires, adding two additional differential pairs (each containing three wires) to the existing setup. This enhanced configuration allows for SuperSpeed data transfers, which are much faster than the capabilities of USB 2.0.

When you peel the outer shield of a USB cable, you’ll often see exposed wires in different colors. These color-coded wires serve distinct purposes within the USB cable:

- Red wire:This wire is used to carry the positively-charged electric power, providing a direct current supply.

- Black wire: This is the ground wire, serving as the return path for the electrical current.

- White wire:This wire is used for the positive data signal (D+).

- Green wire:This wire is responsible for the negative data signal (D-).

In some USB cables, you may encounter a different set of color-coding:

- Orange wire:This wire functions similarly to the red wire, carrying the positive power.

- White wire: This wire acts as the ground wire.

- Green wire:This wire is used for the D+ data signal.

- Blue wire:This wire is used for the D- data signal.

Since not all USB-C cables follow the same color-coding scheme, it is essential to refer to the specific cable’s documentation or markings for accurate identification. While red and black are commonly used to represent the positive and negative wires, some USB-C cables may use different colors or additional color coding to distinguish various functions and signal lines within the cable. For instance, data wires and other signal lines may have their specific color codes.

For detailed USB C cable wiring diagram and color code, please visit the corresponding blog.

Why Is It Crucial to Ensure Correct Polarity in USB C Cables?

Ensuring the correct polarity in USB-C cables is crucial for several reasons, primarily related to the safe and efficient functioning of devices. Polarity refers to the proper orientation of the positive and negative wires within the cable, which is essential for correct power delivery and data transmission. When the cable polarity is correct, devices receive the power they need in the manner they are designed to handle, preventing damage to sensitive electronic components. Incorrect cable polarity can cause short circuits, overheating, or even catastrophic failure, as devices are not built to handle reversed electrical flows. This can lead to immediate and severe damage to both the power source and the connected device, potentially rendering them inoperable.

Moreover, correct cable polarity ensures operational efficiency by providing a stable and consistent power supply. Devices rely on this stability to function reliably and maintain performance over time. Incorrect polarity can cause devices to malfunction or behave unpredictably, disrupting normal operations.

Additionally, USB-C cables are used not just for power but also for data transmission. Proper polarity is essential for maintaining the integrity of data signals, ensuring reliable and accurate data transfer between devices. Incorrect polarity can corrupt or lose data, particularly in applications where data accuracy is critical.

The potential consequences of incorrect wiring are significant and multifaceted. Improper polarity can result in permanent damage to electronic components and may lead to short circuits, posing fire hazards, especially in environments with flammable materials. Overheating due to excessive current flow is another risk, potentially causing burns or fires. Data integrity is also jeopardized; incorrect polarity can disrupt data transfer, resulting in corrupted files or incomplete data transmission, a critical concern in professional or industrial settings. Moreover, devices damaged by incorrect polarity often fall outside warranty coverage, leading to additional costs for repairs or replacements. This lack of support can leave users without assistance in resolving the issues caused by improper wiring.

What Factors Affect The Quality Of USB Positive And Negative Electrode Wires?

The quality of positive and negative electrode wires in USB-C cables, or any electrical cables, is influenced by several factors. These factors determine the overall performance, durability, and safety of the cables. Here are some key considerations:

- Material Composition

The primary material used for the conductors significantly affects the quality. Copper is commonly used due to its excellent electrical conductivity and flexibility. High-purity copper ensures lower resistance and better performance. In some cases, silver-plated copper may be used for even better conductivity.

The materials used to insulate the wires are crucial for preventing electrical shorts and maintaining signal integrity. Common insulation materials include PVC (Polyvinyl Chloride), polyethylene (PE), and polypropylene (PP). The quality of these materials affects the cable’s flexibility, durability, and resistance to environmental factors. - Manufacturing Process

The precision with which the wires are manufactured affects their performance. Consistent wire diameter and uniform insulation thickness are important for maintaining reliable electrical characteristics and preventing weak points that could lead to failure.

For data integrity and reduced electromagnetic interference (EMI), the way wires are twisted and paired is crucial. Twisted pairs help cancel out noise and maintain signal quality. The tightness and consistency of these twists can impact performance. - Shielding and Protection

Effective shielding is necessary to protect the wires from electromagnetic interference (EMI) and radio frequency interference (RFI). High-quality cables often use a combination of braided shielding and foil shielding to provide robust protection. The materials and construction of the shielding affect its effectiveness.

The outer jacket of the cable provides physical protection to the internal wires. Materials like PVC or TPE (Thermoplastic Elastomer) are used for their durability and flexibility. The quality of the outer jacket affects the cable’s resistance to wear, abrasion, and environmental factors. - Electrical Characteristics

The electrical resistance of the wires should be low to ensure efficient power delivery and minimal energy loss. High resistance can lead to heating and reduced performance. The purity of the conductor material and the cross-sectional area of the wires are critical factors here. These electrical properties can affect signal quality, especially in high-speed data transmission. Proper cable design to minimize unwanted capacitance and inductance is important for maintaining signal integrity. - Environmental Resistance

The ability of the wires to withstand varying temperatures without degrading is important for both safety and performance. High-quality materials and manufacturing processes ensure that cables can operate reliably over a wide temperature range. Exposure to moisture and chemicals can degrade the insulation and conductors. High-quality cables use materials that offer resistance to these factors, ensuring longevity and reliability in various environments. - Compliance and Standards

Compliance with industry standards (such as USB-IF certification for USB cables) ensures that the cables meet certain performance and safety benchmarks. Adherence to these standards is a good indicator of quality. Rigorous testing during and after the manufacturing process helps ensure that the cables meet quality standards. This includes testing for electrical performance, durability, and resistance to environmental factors.

So, the quality of both the power positive and negative wires, as well as the data positive and negative wires, determines the overall performance of the cable. It underscores the importance of adhering to standards and conducting thorough testing to guarantee reliable and high-quality products that meet the needs of users across various applications and environments.

What are the methods to detect the positive and negative wires of USB C?

We all know that USB C cables usually include multiple wires dedicated to power delivery and data transfer. Vbus (positive power), GND (ground power line), D+ and D- (basic USB2.0 data transfer differential pair), RX and TX pins (super-speed data transfer differential pair) are all positive and negative in nature. These wire cores are used to transmit positive and negative power and data between devices.

In today’s world of countless devices, it is crucial to know how to correctly identify the positive and negative wires of USB C. Whether you are tinkering with gadgets, making custom cables, or just ensuring the reliability of the connection, understanding the complexity of USB C wiring can save you a lot of trouble. Let’s dive into the practical methods of detecting the positive and negative wires of USB C to ensure that you can confidently connect your devices without any accidents.

Multimeter Magic:

A multimeter is the best helper to identify USB C cables. Here’s how to use it:

- Set up the multimeter: Adjust the multimeter to the DC voltage setting.

- Probe Placement: Carefully place the red probe on the Vbus pin and the black probe on the GND pin.

- Read the voltage: If the voltage reads positive, congratulations, you have found the positive (Vbus) and negative (GND) wires.

This method is simple and reliable and ensures that you can easily distinguish between the positive and negative power wires. Using a multimeter can also help identify basic USB 2.0 data transfer lines:

Set the multimeter to continuity mode: Most multimeters have a mode that will beep when there is continuity.

- Probe Placement: Place one probe on the D+ pin of the USB C connector and the other probe on one of the internal wires.

- Listen for the beep: The wire that caused the multimeter to beep is the D+ wire.

- Repeat for D-: Similarly, place the probe on the D- pin and test the remaining wires.

Using continuity mode helps ensure that you can identify the correct data wire without an active connection.

Continuity Test:

The continuity test helps you identify the ground (GND) wire in the USB-C cable. Follow these steps:

- Set the multimeter to continuity mode: This mode is usually indicated by a sound wave symbol.

- Touch the probes together: You should hear a beep, indicating that the multimeter is working properly.

- Probe the wires: Place one probe on the metal shell of the USB-C connector (connected to GND) and the other probe on each wire in turn. The wire that causes the multimeter to beep is the ground wire (GND).

This method is particularly convenient because it does not require powering the cable, ensuring safety while testing.

Wire color coding:

While not as reliable as using a multimeter, wire color coding can sometimes help identify the positive and negative wires. Typically, the color code is:

- Red: Positive power (Vbus)

- Black: Ground (GND)

- Green/white: Data wires (D+ and D-)

- RX/TX pair (USB 3.0+ High-speed data): typically blue and yellow, orange and green, etc.

However, wire colors may vary between manufacturers, so be sure to use a multimeter or oscilloscope to verify accuracy.

Using an oscilloscope:

To more accurately identify the USB data positive and negative lines, especially for USB 3.0 and higher speed data lines (RX and TX):

- Connect the USB C cable to the powered device: Make sure the device is turned on and the USB C port is active.

- Connect the oscilloscope probe: Connect the oscilloscope probe to the suspected data line, and the oscilloscope can display the signal waveform of data transmission.

- Observe the waveform: D+ and D- will show the differential data signal at lower speeds (USB 2.0 up to 480 Mbps). The RX and TX pair (for USB 3.0 and above) will show high-speed differential signals (up to 5 Gbps or more).

The oscilloscope allows you to visually confirm the data transmission characteristics to ensure that you correctly identify the data line.

USB C Pinout Diagram:

Reference to the USB C pinout diagram can provide a visual guide to identify the function of the wires. The symmetrical design of the USB C connector makes the pinout a little tricky, but the diagram can clarify which pins correspond to the power and data lines. You can find reliable pinouts in our USB C Pinout Specification document.

Think of your USB C cable as a complex dance partner. Think of the data lines as the nervous system of the USB C cable and the power lines as the muscles. Each line has a specific role, transmitting important information to keep your devices in sync. With the right tools and techniques, you can decode this complex dance and ensure your devices communicate smoothly and efficiently.

By adopting these methods, you will not only master the art of detecting the positive and negative USB C wires, but also improve the life and performance of your devices. Have fun, and may your connections always be strong and reliable!

APPHONE’s Commitment to Quality

At APPHONE, we ensure our USB-C cables meet the highest quality standards through rigorous testing and meticulous manufacturing processes. We use high-purity copper cores in our cables to guarantee excellent electrical conductivity and durability. Our pin designs are meticulously crafted to ensure a secure and reliable connection, reducing the risk of wear and tear. Throughout the production process, we conduct multiple quality checks to ensure that every cable meets our strict standards.

Read More: APPHONE USB Cable Manufacturing Process.

Our USB cables embody our unwavering commitment to quality, setting a standard of excellence across our entire product line. From USB data cables to adapters, fast chargers, audio headsets, and car chargers, each item reflects our dedication to innovation and customer satisfaction.

Understanding the positive and negative wires in USB-C cables is essential for ensuring safe and effective device charging and data transfer. By using methods like visual inspection, multimeter testing, and professional equipment, you can accurately identify and troubleshoot these wires.

At APPHONE, we pride ourselves on delivering high-quality USB-C cables and accessories. Our rigorous testing and innovative manufacturing processes ensure that our products meet the highest standards of quality and reliability. Whether you need USB data cables, adapters, fast chargers, or other accessories, we have a solution tailored for you.

What are the 4 wires in a phone charger?

A typical USB phone charger cable contains four wires:

- Red: Positive power (V+)

- Black: Ground (V-)

- Green: Data positive (D+)

- White: Data negative (D-)

These wires handle charging and data transfer functions.

Does a Type-C charger have red and black wires?

USB-C cables can vary, but they often contain multiple internal wires, including power and data lines. While traditional color coding like red for positive and black for negative may not apply universally, USB-C cables are designed with specific power delivery and data transfer protocols. It’s best to refer to the cable’s documentation or use a multimeter for precise identification.

What is positive and negative about a 12v cable?

Usually; there is a red wire positive or black w/red stripe. And/or the clip has a Plus-sign (+) cut in it. Occasionally; Both wires Black and a red Sheath on positive clip. Black on negative.

What is the negative and positive wire symbol?

When using positive and negative numbers we put a + sign in front of positive numbers and a − sign in front of negative numbers. If there is no sign in front of a number it typically means that the number is positive.

How to identify live and neutral wires?

In many regions, electrical codes mandate specific colors for live and neutral wires. In the United States, live wires are typically black, red, or another color, while neutral wires are often white or gray.

Share This Artcle:

Fast delivery

Fastest delivery within 22 days

Quick proofing

Fastest 3-day proofing cycle

After-sale protection

24-month long warranty

1V1Customer Service

Professional customer service follow-up