Why does the MFI Certified Lightning Cable so expensive? Lightning cable Wholesale

Picture this: You’re sitting at your desk, engrossed in a project

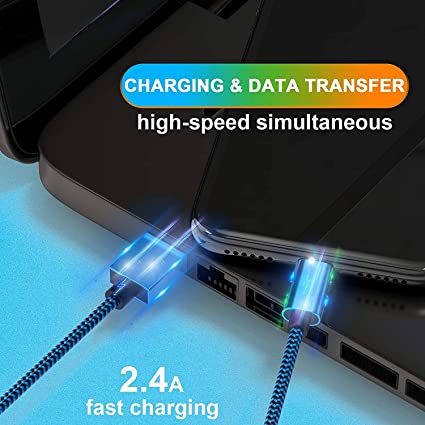

USB cable.

Picture this: You’re sitting at your desk, engrossed in a project

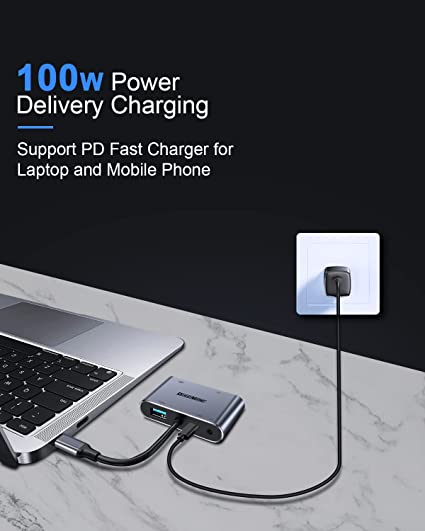

Where Can I Buy a High-Quality Pd Fast Charging Cable?

1 cable

USB-C cables certainly.

Share This Artcle:

Fast delivery

Fastest delivery within 22 days

Quick proofing

Fastest 3-day proofing cycle

After-sale protection

24-month long warranty

1V1Customer Service

Professional customer service follow-up